Yenkqubo yokugoba yecinezela umatshini wokuqhawula , umgangatho wokugoba ubukhulu becala uxhomekeke kwiiparamitha ezimbini ezibalulekileyo ze-engile yokugoba kunye nobukhulu. Xa ipleyiti yokugoba, kufuneka sinikele ingqalelo kule miba ilandelayo, ukuze siqinisekise ubungakanani bokugoba kunye ne-engile.

(1) Ephezulu kunyeemazantsiiimela zokubumba azigxininisi, eziya kukhokelela kwiimpazamo kwimilinganiselo yokugoba. Ngaphambi kokugoba, iimela zokungunda eziphezulu kunye nezisezantsi kufuneka zilungelelaniswe kwiziko.

(2) Emva kokuba isivalo sangasemva sihamba ngasekhohlo nasekunene, indawo ehambelana nayo ishidi kunye nefa esezantsi inokutshintsha, ngaloo ndlela ichaphazele ubungakanani bokugoba. Umgama wokuma we-backstop kufuneka uphinde ulinganiswe phambi kokuba ugobe.

(3) Ukungahambelani okungonelanga phakathi kwesixhobo sokusebenza kunye nesingundo esisezantsi kuya kubangela ukugoba kwakhona kwaye kuchaphazele i-angle yokugoba. I-parallelism kufuneka ilinganiswe kwaye ilungiswe ngaphambi kokugoba.

(4) Xa i-angle yokugoba ephambili inganelanga, ukugoba kwesibini kuya kuchaphazeleka. Ukuqokelela kweempazamo zokugoba kuya kukhokelela ekwandeni kobukhulu kunye neempazamo ze-engile ze-workpiece yokwenza. Ngoko ke, kubaluleke kakhulu ukuqinisekisa ukuchaneka kokugoba unilateral.

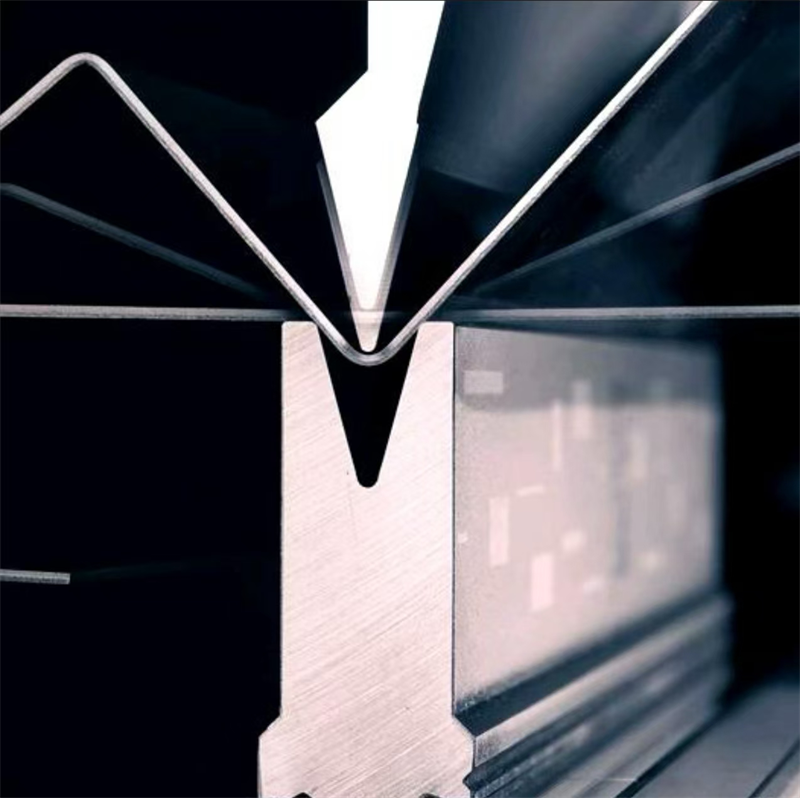

(5) Xa ugobakunyecinezela umatshini wokuqhawula, ubungakanani be-V-shaped groove ye-mold ephantsi ihambelana ngokungafaniyo noxinzelelo lokugoba. Xa kusetyenzwa amacwecwe esinyithi obunzima obahlukeneyo, kuyimfuneko ukuba ukhethe i-groove eyi-V efanelekileyo ye-mold ephantsi ngokwemimiselo, ngokubanzi amaxesha ama-6 ukuya kwe-8 ubukhulu beplate. Okufanelekileyo ngakumbi.

(6) Xa i-workpiece igobile kumatshini wokugoba emva kokudala i-groove emise okwe-V, qinisekisa ukuba umgca we-mold ephezulu, i-edge ephantsi ye-V-shaped groove ye-workpiece kunye ne-edge ephantsi ye-V-shaped groove ye-mold ephantsi ikwindiza efanayo nkqo.

(7) Xa ukugoba workpiece grooved, ukwenzela ukuthintela isixhobo clamping, i-engile Die eliphezulu kufuneka ilawulwe malunga 84 °.

(8)Xa kusetyenzwa isiphelo esinye se cinezela isiqhoboshiumatshini, oko kukuthi, umthwalo wecala elinye, uxinzelelo lokugoba luya kuchaphazeleka, kwaye luluhlobo lomonakalo kwisixhobo somatshini, esinqatshelwe ngokucacileyo. Xa uhlanganisa isikhunta, inxalenye ephakathi yesixhobo somatshini kufuneka ihlale igxininisekile.

Ukuba unamathandabuzo malunga nenkqubo yokugoba yecinezela isiqhoboshiumatshini, ungaqhagamshelana noMACRO nangaliphi na ixesha. Singakunika isikhokelo esikwisiza okanye sevidiyo ukufezekisa eyona mpembelelo ilungileyo yokugoba kunye nokusebenza kakuhle kwinkqubo yakho yokugoba. Wamkelekile ukudibanaMACROnangaliphi ixesha.

Ixesha lokuposa: Dec-19-2024